|

|

02/25/2015 |

We get lots of email, most good, some pointing out where we screwed up. This email from Tom Garry was so much fun to read, I thought that, with Tom's permission, I would share it with everyone: We get lots of email, most good, some pointing out where we screwed up. This email from Tom Garry was so much fun to read, I thought that, with Tom's permission, I would share it with everyone:

Dear Tools for Working Wood:

Please allow me to share the thoughts of a dying man with you. (The doctor recently only gave me 5 or 6 more decades to live).

When I was young, I heard or read somewhere "never be afraid to buy the very best - especially when it comes to tools." That phrase stuck with me throughout my life. A couple of years ago I had to give up my then-current hobby, which was rather extreme and involved several trips to the emergency room, and I took up woodworking as a replacement. I knew very little about hand-tools, other than that I absolutely loved the look, feel, and entire concept behind them. How a man could wield such instruments of beauty and produce equally beautiful and functional pieces of furniture and art using only the power of his body, the direction of his vision, and the touch of his hands was utterly fascinating to me. So I did what any new student would do - I visited You Tube University. There, I was lucky enough to stumble across Paul Sellers and his videos on woodworking. I was hooked. It soon became obvious that chiseling with a sharpened screwdriver and smoothing wood with a massive belt sander was simply not going to get the job done. I needed to invest in some tools.

Through more online investigation, I also discovered Tools For Working Wood, and specifically, the Gramercy hold-fasts. After building my work bench (thank you Paul Sellers) I couldn't wait to hold down my first piece of wood with my new hold fasts, modified with a piece of leather from an old belt. I was amazed at the force that could be applied and the obvious durability these would have through my few remaining decades of life. I had discovered, in a world filled by the biblical flood of cheap imports, in a word - quality.

The next couple of years saw my collection of tools grow, and included the full set of Ray Isles mortising chisels. I was dying (no pun intended) to use them for a REAL mortise. So I made a walnut slant - front writing desk, where the only electrons harmed were in cutting the tapers for the 12/4 walnut legs on my portable table saw. I chopped a dozen perfect mortises with these hunks of solid D2 steel and they laughed at my feeble efforts to punish them. They were taunting me to do something that only they could do. The next couple of years saw my collection of tools grow, and included the full set of Ray Isles mortising chisels. I was dying (no pun intended) to use them for a REAL mortise. So I made a walnut slant - front writing desk, where the only electrons harmed were in cutting the tapers for the 12/4 walnut legs on my portable table saw. I chopped a dozen perfect mortises with these hunks of solid D2 steel and they laughed at my feeble efforts to punish them. They were taunting me to do something that only they could do.

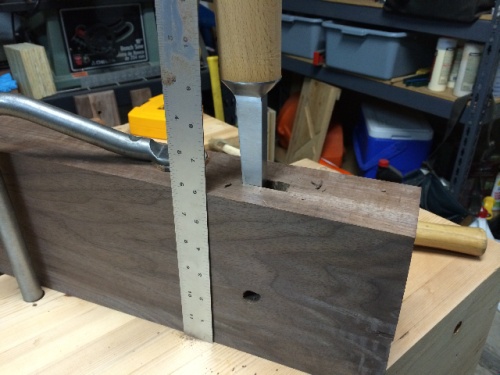

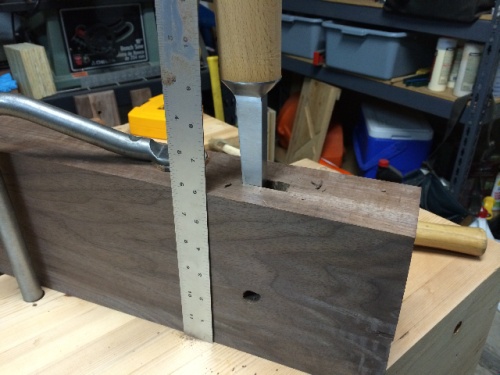

Not knowing if I would survive another Christmas, I revisited my favorite on-line tool store again and discovered the Moxon vice hardware of my dreams! I had an ideal piece of 12/4 walnut left over from my desk build that would be perfect for this ingenious bit of hardware. When my prize arrived a few days later I excitedly examined everything in the kit - and then I saw those 1/2" thick rectangular nuts that would require...be still my heart...a 1/2" wide, 1" long, and very, very deep mortise! I could almost hear my English mortising chisels shudder in my tool cabinet.

When the day of mortising finally arrived, I wanted to play some gothic-choir-chant-type music and wear a dark hooded robe as I lifted the mighty 1/2" chisel, named Mr. Mortise, in the air. Alas, I had no such chants, or hooded robe, so I played the Monty Python segment where they walked through the town calling "Bring out ye dead!" followed by a rhythmic 'thud' of a drumbeat. After laying out the location of the mortises twice (I was so excited I got the location wrong the first time) it was finally time to strike Mr. Mortise on the head with a mallet and see how far I could go. The mortise began to take shape and I was now swinging the mallet over my head and delivering as forceful an impact that I could muster. Mr. Mortise plunged deeper and deeper into the abyss of walnut sheering huge chunks of debris out of his way. The sides of the mortise actually became polished after brushing shoulders with Mr. Mortise time after time again. When the final blow fell silent, I dropped my stainless rule into the mine shaft to check depth: 4 1/8" deep. Straight down. No drift. No problem.

I think the finished Moxon vice looks pretty nice, if I do say so. I was so proud of surviving another year of my fatal disease called "natural causes" that I rewarded myself with the Gramercy dovetail saw. Oh I can't wait to drive that Formula 1 car around a long racetrack of joinery!

So, my toolmaking heroes of the North, I would like to offer a very sincere 'Thank You' to everyone who was involved with bringing peace to a man who's years were once numbered. I'm happy to report that because of you I appear to be in remission and am as healthy as a horse. Never be afraid to build the very best - we will buy it.

Best Regards,

Tom Garry

The Woodlands, TX |

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

We get lots of email, most good, some pointing out where we screwed up. This email from Tom Garry was so much fun to read, I thought that, with Tom's permission, I would share it with everyone:

We get lots of email, most good, some pointing out where we screwed up. This email from Tom Garry was so much fun to read, I thought that, with Tom's permission, I would share it with everyone:  The next couple of years saw my collection of tools grow, and included the full set of Ray Isles mortising chisels. I was dying (no pun intended) to use them for a REAL mortise. So I made a walnut slant - front writing desk, where the only electrons harmed were in cutting the tapers for the 12/4 walnut legs on my portable table saw. I chopped a dozen perfect mortises with these hunks of solid D2 steel and they laughed at my feeble efforts to punish them. They were taunting me to do something that only they could do.

The next couple of years saw my collection of tools grow, and included the full set of Ray Isles mortising chisels. I was dying (no pun intended) to use them for a REAL mortise. So I made a walnut slant - front writing desk, where the only electrons harmed were in cutting the tapers for the 12/4 walnut legs on my portable table saw. I chopped a dozen perfect mortises with these hunks of solid D2 steel and they laughed at my feeble efforts to punish them. They were taunting me to do something that only they could do.

A few years ago I started buying tools from lie-nielsen and other high-end people and there's nothing like using a well-built, well thought out tool. I get a real joy from using these tools. I bought a blue spruce mallet and now I have bought a Bruce Bluespruce awl which I cannot wait to get and start using.

Alas, I have bench chisels, skew chisels, carving chisels, butt chisels, paring chisels, but nary a mortise chisel. I now see the folly of resistance to CAS, chisel acquisition syndrome. I see that resistance is futile... I don't know where I heard that, but it rings with truth. A chisel, a chisel, a kingdom for a mortise chisel! I'm not dead yet!

Michael Price

Y'all really do need to check out that dovetail saw, by the way. My current project has about 130 pins/tails on it and boy is it sweeeet!

A good day is a new tool arriving,a cigar, and a cup of coffee.